I didn't seem to get any action shots this time -- it's hard enough to get yourself in the upside down hull, let alone with a camera. I was able to accomplish all the 'inside' tasks: making fore and aft beam mounting flanges, the deck mounting flange on the center BH and transom, the compression strut between bow stiffeners, the tapping plate for the deck eye, and a sealing coat of resin along keel.

I mounted the T6061 aluminum plate under flanges (best done upside down). A trick I used in hard-to-reach areas of bow and transom: take a cloth towel in a plastic bag and shove, wedge, or brace into the small place. It works wonders to hold tape (plus or minus peel ply) in place and removes easily when the resin is cured.

Strut at stringers.

Forward and aft beam mounting flanges. I would pre-wet the glass on a sheet of plastic, then place each layer individually. For the double bias I cut the plastic around the glass then applied both, removing the plastic before the next layer. This plastic backing kept the pieces full-size as they were applied. In the smaller confines of the aft/transom area where I could sometimes only get one arm and shoulder in at a time, this helped with even the bi-directional. I finished these with the usual poor man's vacuum bag.

I wanted to shape the keel before putting on the deck in case I sanded too close to the interior laminate. I rough cut the keel foam with a Japanese pull saw, then attacked with the long board and 36 grit.

Templates at several form stations help guide the final shape. Just starting here with the keel still square.

I will make a qualification on my previous statement of the sand-ability of QuickFair. It's not exactly like foam. For the screw holes and vertical plank joins, it's as if the QF isn't there. The longboard is going perpendicular to the join at all times. Also, the join between the halves was easy. But the join where the planks butt against the keel foam required some extra attention. They're parallel to the action of the longboard and it's difficult to control the rocking motion as the board goes over the slightly harder QF. This can leave a slight hump or angle instead of the smooth curve that would naturally develop if it was exactly the same as the foam. I broke the rules and with light pressure went perpendicular to this seam just before my last pass of the board -- it disappeared.

This was my first experience with the longboard. An amazing tool. I have the 3M Hookit -- flexible. I caused myself a little grief right off the bat by turning the board perpendicular to the keel and sanding the keel to match the hull side near the bow. Of course, the side was a little low, but I didn't want the keel low there -- I just hadn't started thinking (I wanted them to match, right?). Lesson learned. You can only sand high spots, and if you use the tool wrong, you get the wrong result.

Here you can see how thin I needed to sand the foam to achieve the desired shape (that's the shadow of my hand). The plans call for some extra reinforcement if you sand to (or through) the laminate in the keel area. I decided to place an extra piece of tape on each side near the transom. You can see how using the 3/4 inch foam at the keel gives a larger flat surface, so the tape does not go up on the hull sides near the transom. I will place this extra lamination on the second float at the same time as taping the keel.

The final shape at the transom. The deck will be next, then final shaping before glassing.

I took a trip down to California to see my daughter at college. I drove straight down, toured the campus, camped at the beach with her for several days, and visited with my brother and sister-in-law.

I'll share a couple pictures to entice people to visit the West Coast. These pictures are all California -- the rest of the time I was making miles (3000 in 11 days).

Big Sur, a wild part of the southern coast, visited on the way down.

After leaving Santa Barbara, I went to Yosemite -- a National Park and World Heritage Site. I'd never been to Yosemite. Having the Eurovan makes me realize I've done a lot of international travel, but seen only a fraction of my own country.

Taft Point (behind me is the view point) with a 3000 foot drop to the valley floor where I camped. El Capitan is in the distance across the valley. Mid 70's and sunshine every day.

Half Dome as seen from Glacier Point. The pass to the eastern side is in the distance. So much granite!

El Capitan, Half Dome in distance, at sunset from Tunnel View.

El Capitan, at sunrise from Valley View with Merced River. One of the classic sights of Yosemite is all the waterfalls coming over the high cliffs, but there is very little water after the end of summer. I plan to return in the spring.

Cathedral Rocks by (full) moonlight, from the valley floor.

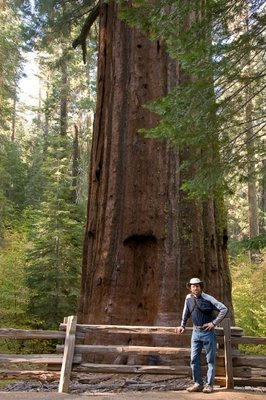

Tuolumne Grove of Giant Sequoia (largest living organism by mass, found only on west side of Sierras. The tallest is a relative, the Coast Redwood, also found in California).

I drove east across the Sierra Nevada on Tioga Pass. Here's lunch at 9950 feet. This road closed because of snow two weeks later.

Searching for Fall colors. The classic in eastern Sierra are Aspen. I was a little early, but they were still pretty. Lee Vining Valley.

Mono Lake with tufa looking at the Eastern Sierra at sunrise. The ecology of the Great Basin is amazing (200,000 square miles with no outlet to the Pacific). I stopped to hike in several more valleys, then headed north.